| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : Weite ceramics

Model Number : 53N61#

Certification : ISO9001

Place of Origin : Jiangsu, China

MOQ : 1500piece

Price : Negotiate

Supply Ability : 100000 per month

Packaging Details : carton

Orifice : 11mm

colour : Pink

Features : High mechanical strength

Model : 53N61#

advantage : Good electrical insulation

application : Various welding and cutting operations

place of origin : Jiangsu, China

Molding method : Dry pressing/Hot pressing

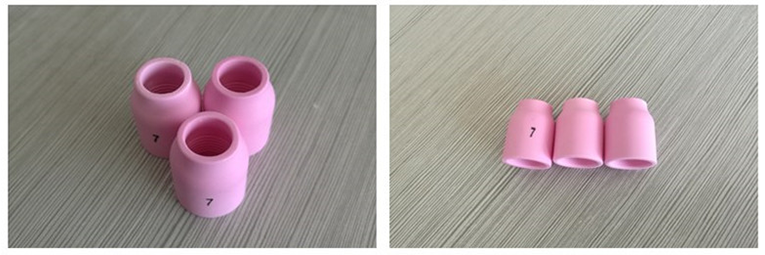

11mm Alumina Welding Protective Sleeve With High Temperature Resistance

Alumina nozzle 53N series 61#

Main ingredients: 95% Al2O3 (alumina)

Thermal characteristics:

Electrical characteristics:

Alumina ceramics have better conductivity, higher mechanical strength and high temperature resistance. As a welding nozzle made of alumina ceramics, it has excellent high temperature resistance, high melting point, and no decline in mechanical properties. It can be used at high temperatures without affecting product performance or bursting. Good corrosion resistance, regardless of strong acid (except hydrofluoric acid), strong alkali (except hot alkali), inorganic organic salts and other conditions will not be affected.

| Size | Part Number | Length (mm) | Orifice (in) | Orifice (mm) | Torchdesign |

| NO 3 | 53N23 | 17 | 3/16 | 4.0 | 24 |

| NO 4 | 53N24 | 17 | 1/4 | 6.5 | 24 |

| NO 5 | 53N25 | 17 | 5/16 | 8.0 | 24 |

| NO 6 | 53N27 | 17 | 3/8 | 9.5 | 24 |

| Size | Part Number | Length (mm) | Orifice (in) | Orifice (mm) | Torchdesign |

| NO 4 | 53N58 | 26 | 1/4 | 6.5 | 20/24/25 |

| NO 5 | 53N59 | 26 | 5/16 | 8.0 | 20/24/25 |

| NO 6 | 53N60 | 26 | 3/8 | 9.5 | 20/24/25 |

| NO 7 | 53N61 | 26 | 7/16 | 11.0 | 20/24/25 |

| NO 8 | 53N61S | 26 | 1/2 | 12.5 | 20/24/25 |

| Size | Part Number | Orifice (in) | Orifice (mm) | Torchdesign |

| NO 10 | 53N88 | 5/8 | 16.0 | 17/18/26 |

| NO 10L | 53N88L | 5/8 | 16.0x70 | 17/18/26 |

| Short | 53N89 | 15/16 | 24 | 14/18/26 |

| Material Project | Alumina AL203 | Silicon carbide sic | Silicon nitride sin | Silicon nitride sin | ||||

| Color | Ivory | black | black | Milky white, gray black | ||||

| Content(%) | 99.5 | …… | …… | …… | ||||

| Main features |

|

|

|

| ||||

| The main purpose |

|

|

|

| ||||

| Density | Kg/m³ | 3.9*10 | 3.16*10 | 3.3*10 | 6.0*10 | |||

|

Mechanical behavior

| Vickers hardness | Gpa | 16.0 | 23.0 | 14.0 | 13.2 | 12.7 | |

| Flexural strength | Mpa | 360 | 450 | 1020 | 1000 | 1470 | ||

| Compressive strength | Mpa | 2350 | …… | …… | …… | …… | ||

| Fracture toughness | Mpa | 4 | 2-3 | 7 | 4-5 | 4-5 | ||

|

Thermal performance

| Linear expansion coefficient | 40-400℃ | ×10-5/℃ | 7.2 | 3.7 | 2.8 | 10.5 | 10.8 |

| 40-800℃ | 8.0 | 4.4 | 3.3 | 11.0 | 11.3 | |||

| Thermal conductivity | W/(m·k) | 32 | 200 | 27 | 3 | 3 | ||

| Specific heat | J/(kg·k) | 0.78*10 | 0.67*10 | 0.65*10 | 0.46*10 | 0.46*10 | ||

| Thermal shock resistance (in water) | ℃ | 250 | …… | >800 | 300 | 350 | ||

| Electrical performance | Dielectric strength | V/m | 15*105 | …… | 13*105 | 11*105 | …… | |

| Volume resistance(20℃) | Ω·cm | >1014 | 108 | 1014 | 1013 | …… | ||

| Dielectric constant | …… | 9.6 | …… | 9.9 | 33 | …… | ||

| Loss factor | ×10-4 | 10 | …… | …… | 520 | …… | ||

Packed in carton

In addition to common sizes and specifications, our company accepts drawings and samples for customization. If necessary, please contact our company directly.

1. Are you a businessman or a manufacturer?

We are a company, we have our own factory

2. How long is your delivery time?

Negotiable

3. Can the product be customized?

Can be customized

4. What is the product packaging?

Carton or according to customer requirements

5. What other products does the company produce?

Welded ceramic nozzles, welded ceramic liners, electronic ceramics, textile ceramics, etc.

|

|

Corrosion resistant 11mm 53N61 alumina ceramic welding nozzle Images |